You are here

|

The galvanized steel coil (GI) consists of at least 97% Zinc, with less than 0.3% Aluminum and solidified at 460℃ high temperature. One main feature of galvanized steel is its excellent corrosion resistance from sacrificial protection of the zinc. When the zinc layer on the surface isolates the steel sheet from atmosphere, it is able to prevent corrosion and keep long lasting life on the substrate. Furthermore, the features of this products are economic, various, and fulfill different requirements and applications, providing high added-value. Lately, the galvanized steel sheets are commonly used in many fields such as architectures, 3C products, home electronic appliances, color coating and living goods, etc. |

|

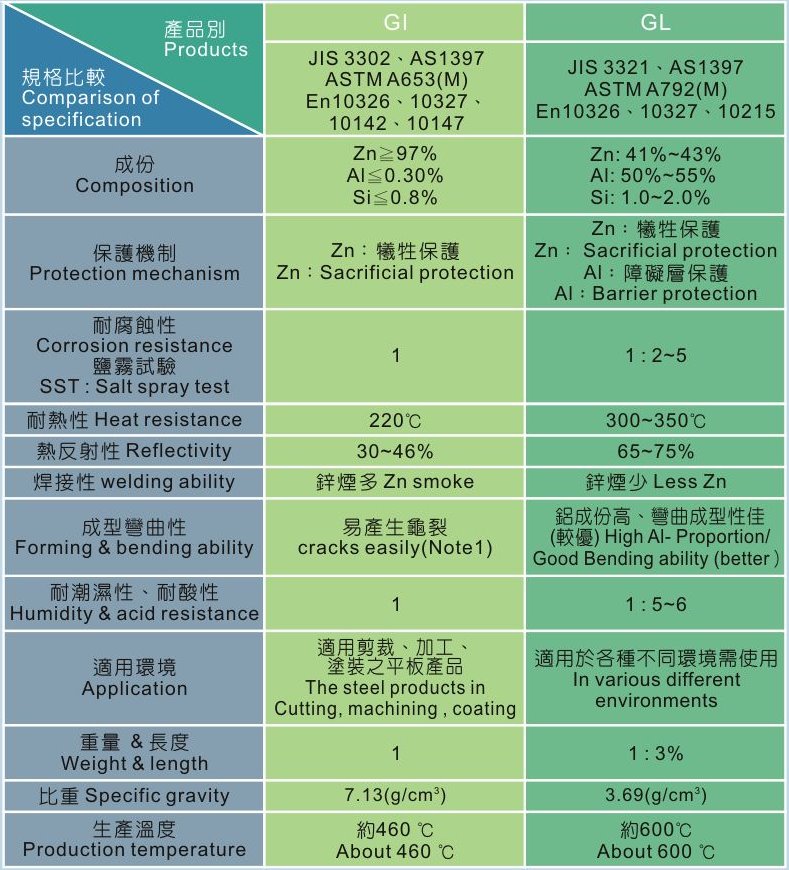

Al-Zn alloy-coated steel sheet has high corrosion resistance. It is also named GL. The surface is formed with diamond look spangles. 55% Al-Zn alloy-coated steel coils (GL) consists of 55% Aluminum, 43.4% Zinc, and 1.6% silicon, solidified at high temperature of 602℃. Its structure is compound by Al-Fe- Si-Zn, and become a protection layer to prevent corrosive penetration. GL steel sheets are commonly used in different fields, applications, corrosion resistance, and pre-painted products as well. In the following table, it shows the classifications and features of GL steel surface treatment. 【Surface treatment and Classifications】

|

|

Corrosion Resistance: Heat Resistance / Heat Transmission and Reflectivity: Weight-saving: Comparison Table of GL / GI:  |